Cleaning machines

Sweeping, swivelling and turning

Sweepers by WESTERMANN provide clean surfaces. Feed treatment augers aerate and prepare sticky feed in such a manner that it becomes tasty again for cattle. To ensure that everything runs smoothly, WESTERMANN installs LFD bearings in its machines.

You cannot make an omelette without breaking some eggs – and where you till the land, you will create dirt. The WESTERMANN company from Meppen offers both self-propelled sweepers as well as those trailed by tractors. WESTERMANN sweepers clean very dirty floors – floors that following the harvest or other trips to the field clearly show the signs that heavy machinery has been operated in clayey fields or floors in stables that have become soiled with cow dung – an easy task for WESTERMANN sweepers.

The mounted sweepers by WESTERMANN are all-rounders for agricultural applications. When traces of clay, farmland and harvest firmly adhere to roads and streets, they are in their element. When it is time for the “spring cleaning” of farmyards and stables, these machines are at the ready with full power.

Radial sweepers for challenging applications –

with precise LFD bearings

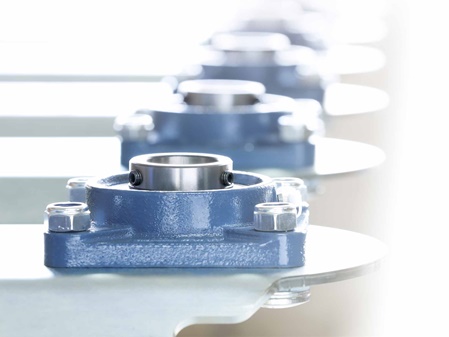

The various housing bearings in which the axles and shafts run, must also deliver their full potential. WESTERMANN uses housing bearings, in particular pillow block bearings as well as cast flange bearing housings. LFD flange bearings made of sheet steel are also used in the event of lighter machines.

Experience has shown that these LFD components provide the necessary precision and service life for the requirements, which in part are very challenging. Additionally, the seals perform exactly in the manner demanded by this environment. The various bearings fulfil their tasks with distinction, although they are usually mounted to the machines visible from the outside without an additional protective housing, as is the case with most other applications.

Rejected feed becomes attractive again

Feed that has come into contact with the animal’s saliva and is now sticky, will be accepted again by the cattle after mixing and aerating. Here, the LFD bearings used by WESTERMANN provide reliable service even though the sticky feed mass is heavy and inhomogeneous. LFD bearings absorb the forces that occur at the shafts and ensure the secure operation with a long service life.

Application diversity, a central benefit

WESTERMANN machines are operated in environments with a high occurrence of dust, dirt and moisture, both in summer as well as in winter with strongly varying temperatures. Even when the sweepers and feed preparation machines are in their element, the bearings will not become contaminated due to the precise LFD seals. The utilised flange bearings are constructed with a closed design with a precisely dosed amount of grease.

The inner components of the LFD bearings are protected against the ingress of contamination by means of special seals. Furthermore, the optimal amount of grease provides its contribution to this. This is of an invaluable advantage to the designers and mechanical engineers of WESTERMANN – and of course to the farmers that benefit from the high-performance and long-lasting support during sweeping, swivelling and turning.