LFD-Bearings

Economical and ecological:

Technology in a well-balanced ratio

LFD engineers energetically and intensively work on in-house, environmentally friendly products, in order to solve the tasks in the respective applications with distinction. We provide our customers from the agricultural sector with mature products and work on the further development and optimization. The usage of in-house test benches at LFD enables us to achieve the ideal further development of our products in close cooperation with our customers.

Insert rolling bearings and units

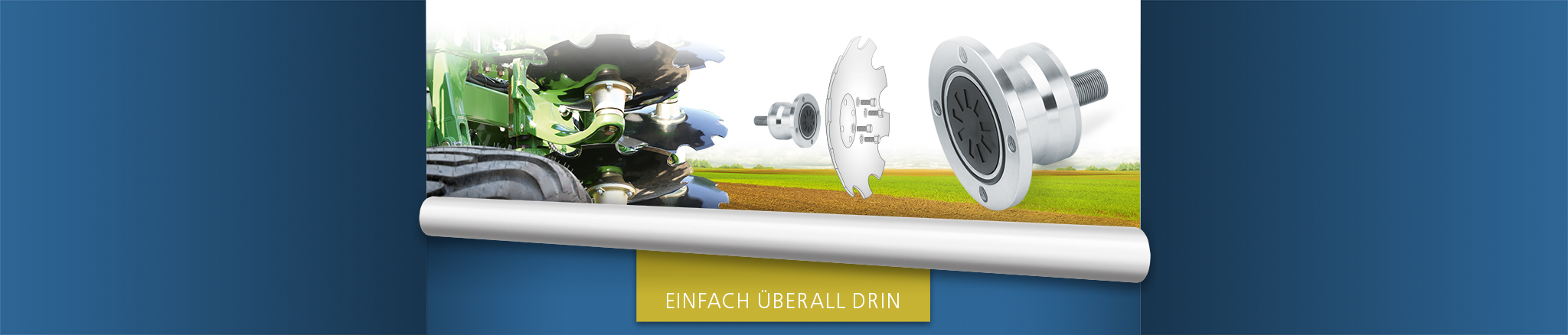

Insert rolling bearing units are used very frequently in agriculture. An insert rolling bearing unit is comprised of a deep groove ball bearing with a spherical outer ring and a housing made of grey cast iron or formed sheet steel.

In this manner, the LFD insert rolling bearings and the matching housings form a unit ready for installation: Housing bearings, pillow block bearings, flange bearings. The special aspect of the insert rolling bearing units is their capacity for compensating misalignments and shaft deflections.

The inner ring of an insert rolling bearing can have the width of the outer ring or depending on the specific application, the inner ring is extended on one or both sides. The attachment of the LFD insert rolling bearings on a shaft is performed with set screws or with an eccentric ring.

Due to the fact that heavy contamination with dirt is to be expected in agricultural usage, the LFD Group places a particular emphasis on application-optimized centrifugal discs, which provide additional protection against the ingress of foreign matter. The centrifugal discs are secured to the inner ring of the UC insert rolling bearing and are designed custom-fit with a minimum gap to the outer ring, ensuring that no additional friction occurs.

Insert rolling bearing units of the LFD Group have been used for many years in various industry sectors such as agriculture as well as in conveyor and drive technology. This includes all variants: Housing bearings in general and flange bearings and pillow block bearings specifically.

Selection of the lubricant is crucial

An optimal film of lubricant is essential for a long service life, which under prolonged use and continuous load prevents the metallic contact of the ball with the bearing track.

In addition to the correctly dosed amount of lubricant, which safeguards that all function surfaces are supplied with sufficient lubricant at all times, the selection of the lubricant is crucial for a long service life.

Just like the sealed standard deep groove ball bearings, the insert rolling bearings are filled with lithium soap grease, which under normal operating conditions is sufficient for the service life of the bearing. Because LFD bearings must achieve their service life under differing and harsh operating conditions that match the application, the use of special lubricants is unavoidable instead of the standard lubricant.

For example, in certain usage cases it is necessary to use lubricants with solid lubricant additives, in order to withstand extreme pressure loads.

An additional important characteristic during the grease selection is the temperature behaviour of the respective applications or the necessity of conducting heat away via the lubricant; however, this only applies in the event of oil-circulating lubrication.

For example, the LFD Group works with greases, which have been approved by the US DRUG ADMINISTRATION as an H2 lubricant for the officially monitored livestock breeding as well as on poultry farms. Therefore, in addition to the other factors, which play an important role during the selection of an bearing, the selection of the right lubricant is of particular importance. For this reason, the engineers of the LFD Group are happy to be of assistance during the application-related selection of the optimal lubricant.

LFD products and agriculture research

Increased load – no problem!

Of course, the load on the bearings forms a very important factor during the selection of an bearing. The LFD Group has the suitable answer in its product range for an increased load.

Two-row LFD angular ball bearings are components with solid outer and inner rings and are able to absorb high radial forces and axial forces in both directions. Different cage variants such as polyamide, brass or sheet steel cages are refined according to the respective application and available accordingly. Likewise, the angular ball bearings can be delivered in open and sealed variants.

Two-row LFD angular ball bearings with double-sided seal faces or cover plates are filled with lithium soap grease and as a result are maintenance-free. These are for example used in disc harrows. In addition to the two-row angular ball bearings, cylinder and tapered roller bearings are a permanent component of the LFD product range. For highest loads, LFD utilizes roller bearings in different applications.

Cylinder and tapered roller bearings of the LFD Group are utilized in different versions in drive engineering, axles and bogies of agriculture as well as construction equipment.

Applications using LFD bearings

As already stated above, the products of the LFD Group are used in a large variety of applications in agriculture as well as in construction equipment. The LFD Group already counts notable manufacturers of transmissions and axles to its satisfied customers. Applications are for example transmissions, disc harrows, axles, bogies, wheels, rollers and much more.

Testing continues

The LFD Group has its own test benches in order to continuously verify the high-quality standard of the LFD bearings and to be able to perform service life analyses in-house. On our test benches, the bearings can be loaded either in an axial or radial manner. Furthermore, a combined load is also possible.

In the course of the test process, the test conditions such as the temperature of the oil-circulating lubrication, the test forces and the engine speed are monitored continuously. During testing, these test conditions can be kept constant or they can be adjusted accordingly. The test is documented with the relevant test conditions and characteristic values during the entire test phase.

Read more: