Compact disc harrows

Tough conditions, reliable performance

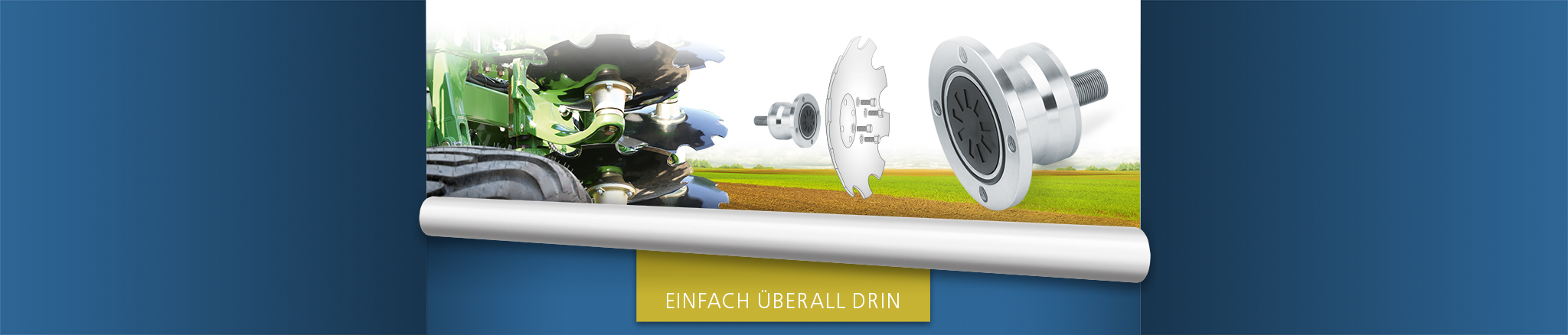

Foreign matter and exposure to dirt are the key issues in regard to the compact disc harrows. How do the bearings of the harrow hollow discs hold up to the challenging conditions encountered on the field? In the AMAZONE compact disc harrows, the LFD antifriction bearings run fully encapsulated and protected in housings and as a result can provide their full capacity for many years.

High marks on the field

The angular ball bearings of the harrow discs, which prepare the soil on the AMAZONE compact disc harrows, are protected by sealed housings at the manufacturer BBG Leipzig.

Each of the two-row angular ball bearings runs in its own housing. The disc itself simultaneously serves as the cover for the housing.

Dirt, dust, and moisture are kept outside, while the open angular ball bearing separated by the steel can deploy its excellent capability in the protected surrounding.

As a result, the work on the field is performed absolutely reliably. The hollow discs are arranged in two rows positioned behind each other.

The cutting angle is predefined, while the offset between the disc rows can be adjusted. The hollow discs are spring-loaded with elastic rubber and just like the trailing wedge ring roller operate maintenance-free with LFD bearings.

Reliability tested on the field

The AMAZONE company regularly has its compact disc harrows tested for reliability and operational efficiency. The German Agricultural Society (DLG) tested the AMAZONE Catros-TS for its market launch with a trailed, separate chassis and determined excellent performance values. In addition to the work quality, the testers of the agricultural magazine “DLZ Agrarmagazin” in particular praised the low drag resistance.

The bearings intended for the use in the compact disc harrows were also run on the test benches of BBG Bodenbearbeitungsgeräte Leipzig GmbH & Co. KG in endurance testing. Here, LFD proves its operating performance on a level that can be considered as the top reference value for quality.

Balanced play of the forces

Each operation is a great feat of strength for the technology. With greater working depth and increasing velocity, the inertia, tensile and compressive forces rise, which the bearings of the hollow discs must absorb and distribute.

With the Catros+, a working depth of up to 15 cm can be achieved. Additionally, a ballasting is possible, in order to safely achieve the set working depth. A large force is applied on the rough arable soil with a great deal of precision. The Certos achieves a working depth of up to 20 cm.

Excellent test results throughout

Both the specialist magazine “Agrar” as well as the DLG performed tests on the AMAZONE compact disc harrows. Their proverbial reliability is due to the sound workmanship and high-grade technology. BBG Leipzig attests performance values to LFD Wälzlager GmbH in accordance with the in-house operating testing for the utilised angular ball bearings – also for long-term operation under hard work usage.

Those that rely on the annual yield of their fields are familiar with the extent of the work that is required until the barns and silos can be closed in autumn. Technology is required that is reliable down to the last detail, enabling a rich harvest at the end of the season. Bearings manufactured by the LFD Group are produced with the greatest precision for the reliable operation of these machines.

Further informations: www.lfd.eu