Irrigation technology

Reliability is key!

When the sun beats down and no rain has been forecast, then modern agriculture relies on hose reel irrigation machines by Beinlich. Here, LFD bearings belong to the most important components of these machines.

If plants are to grow, they must be watered. Any gardening enthusiast knows this. However, in the context of the agriculture sector, this no longer involves a watering can, but instead requires science. The following questions arise in connection with this: How much watering for which plant, from when and at which time intervals? The answers depend among others on the weather, the type of soil, its inhomogeneity and the soil moisture.

In the agriculture sector, factors such as efficiency, water and energy saving, environmental compatibility and workload play a crucial role. In regard to this, agronomists, institutes and trade associations provide important information and decision guidance on the irrigation practice.

After all, large areas are involved and the yield is the decisive factor. Reliable and efficient technology is required for this, in order to be able to survive with high productivity in the face of tough competition.

Very good performance

of the Beinlich irrigation machines

The Beinlich company has been developing hose reel irrigation systems for more than 40 years.

The basic principle of the hose intake powered by turbines has proven to be the best one and today still forms the basis of the largest irrigation machine in the world. However, the control technology, the operation and driving safety as well as the operating comfort have been fundamentally developed further.

The irrigation water is conveyed in elastic special polyethylene hoses, which are laid out at up to 1000 m in the field. During the irrigation procedure, the PE hose must be wound back on the reel at a precise constant speed. Only in this manner can the desired amount of precipitation be applied accurately.

Today, Beinlich is the only leading manufacturer of large-scale machinery that offers lengths of 1000 m. With the use of a machine installation, up to 8 ha can be irrigated.

Increase productivity

with mobile irrigation technology

It goes without saying that the Beinlich reel drum irrigation machines are fitted with the latest electronic control technology. The mechanical components of the machinery that are ever-increasing in size, receive a growing importance. These must be designed for extreme strain: The enormous tensile forces and long PE hoses as well as the extremely large stresses acting on the rotating parts must be absorbed by high-grade machine components. This includes bearings by LFD in different versions. Only in this manner can the flawless function be ensured for many decades.

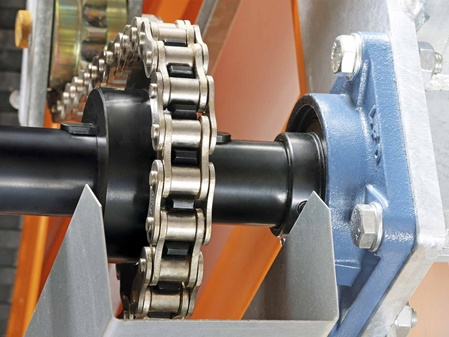

A few examples should be provided: The rotating steel drum is equipped with a stainless steel axle, which ends in LFD pillow block bearings that are installed in a flanking manner.

The weight of the heavy steel drum is supported at this point and here the high tensile forces of the hoses rubbing against the ground during winding up are absorbed.

The triple roller guides of the reel cart are designed for robustness, as enormous lateral forces are generated during the winding up of the hose. Precise winding up along the entire width of the drum is required, which is extremely difficult, when it has been laid down laterally in the track.

Deep groove ball bearings by LFD have been installed in the bushing of the reel cart. They support the function of the guide bolt, which follows the groove of the spindle shaft.

In turn, the spindle shaft is supported on both sides with accurately adjusted LFD flange bearings, ensuring fault-free operation.

For each requirement

the right bearing solution

The functional requirements presented here are only in regard to the hose for the water transport. These alone provide an impression of the wide performance range that LFD must cover with its high-quality bearings, in order to meet the uncompromising requirements set by Beinlich.

This is not only in regard to loads and construction shapes. It is also in regard to the environment to which the hose reel irrigation machines and the LFD bearings are exposed: Under the toughest conditions in open land, such as sun, snow, rain, wind, dust and sand, the LFD bearings master their tasks with brilliance.

For this reason, it is not an exaggeration to award the bearings by LFD the special quality label “durable open land technology”. They have more than earned it with their tireless work on fields all over the world.

More information: www.lfd.eu/en