Spherical plain bearings and rod ends

Focused hydraulic competency

Hydraulic cylinders are constructed in different types and performance classes. Kandziora Metallbearbeitung GmbH located in Niederlangen distinguishes itself by the fact that many of the processed components originate from their own in-house production.

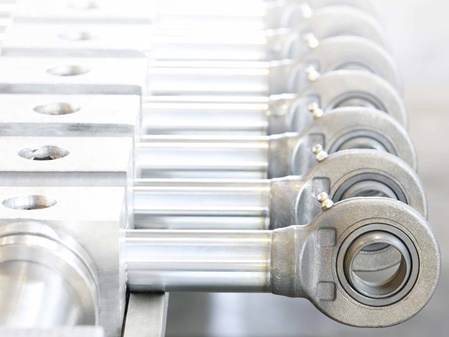

As a result, the highest standard can be guaranteed on all levels of the production line. Mainly LFD rod ends of the type GF … DO and GK … DO are used; when higher load factors are required, spherical plain bearings of the type GE … FO are utilised, usually in welded versions on piston rods and cylinder bases. Both companies agree on the important matters: Kandziora and LFD both place a great value on the highest possible quality and traceability of their own products.

For this reason, the hydraulic cylinders and spherical plain bearings are continuously further developed according to all requirements set by the customers and the market. Similar considerations apply to each individual work step such as cutting, welding, assembly and coating, as only regular optimization will lead to optimal solutions.

Optimal consistent quality

At LFD Group an optimal consistent quality is especially important for agricultural engineering and other mobile machinery and is safeguarded on the one hand by means of the installed in-house laboratory facilities and on the other hand the service life test benches located at the Dortmund location.

With the use of the latest 3D CAD software as well as complex kinematics and flow simulators, the engineers and technicians of the Kandziora company in this manner develop powerful hydraulic cylinders, which meet all set requirements.

Experience meets innovation

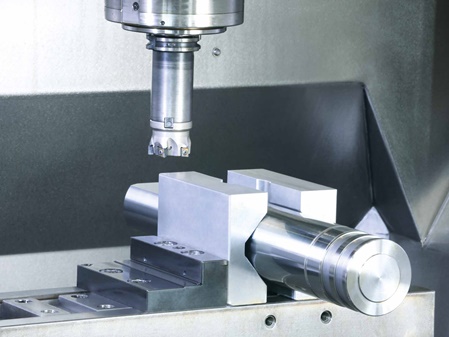

The production location offers a surprisingly large in-house manufacturing depth with high fabrication competencies as well as computer-based machinery and plant facilities. This includes CNC machine tools, systems for heat treatment, electro-plating and painting facilities, automatic assembly and testing equipment.

In-house production with the greatest precision

The greatest precision can be guaranteed in the area of the required surface quality and measurement tolerances for the individual components of the hydraulic cylinders due to the machining with simultaneous 5-axis machining centres. These can all be produced in-house and additionally special application-specific requirements can be immediately included in the planning and then implemented.

The hydraulic cylinder with rod ends and spherical plain bearings of the LFD Group have versatile applications in agricultural engineering, in construction equipment, in disposal technology, in commercial vehicles, mining, forestry as well as in the offshore area.

Welding robots are utilised during the fabrication of the hydraulic cylinders in order to ensure even, oil-tight weld seams under consideration of the various areas of use of the hydraulic cylinders. When using hydraulic cylinders in machines that are utilised in an environment with a high occurrence of dust, dirt, moisture as well as pieces of rock, Kandziora for example makes use of a gaiter in order to protect the piston against external influences.

The spherical plain bearings of the LFD Group are utilised in order compensate possible alignment errors under these rough conditions, but also to absorb the high forces that occur.

LFD spherical plain bearings prevent lateral forces from being transferred to the cylinder in order to counteract a possible risk of the buckling of the cylinder and also to protect the seals against excessive wear.