Mobile work machines

Spherical plain bearings in mobile work machines

Spherical plain bearings are used whenever misalignments must be compensated and extremely high force loads must be absorbed. One focal point is formed by mobile work machines from the industry sectors of agricultural and forestry machinery, construction equipment, all types of commercial vehicles as well as lifting and transport vehicles.

GÖDDE MASCHINENBAU GmbH among others produces boom mowers, accessory units for outriggers, pruning shears and concrete mixer buckets.

“We mainly use LFD standard solutions”, warehouse manager Frank Oldiges explains. LFD spherical plain bearing technology is a strong brand of the LFD Group. The company often utilises the spherical plain bearings of the type GE40-DO. “We have made the experience that maintenance-free spherical plain bearings in the swivelling arm will begin to squeak after two to three months”, he explains. For this reason, bearings that can be re-lubricated are the better solution for the products of GÖDDE Maschinenbau GmbH. Overall, the maintenance-free bearings are often less suitable for the hydraulic system, as the load on the spherical plain bearings is too great in many application types.

Buyers require a quick orientation

For this reason, the online recoding guide is very helpful! It works very easily and provides quick information on a suitable product. Example: As a customer, are you looking for a specific spherical plain bearing or a rod end, however you are not familiar with the LFD product designation? No problem.

The LFD online database contains more than 20,000 designations of spherical plain bearings or rod ends. You enter what you are familiar with – even designations of third-party suppliers – and you will find the corresponding LFD product.

A spherical plain bearing tilts, swivels, turns and moves. This is the difference to normal bearings. The areas of application are particularly diverse. As a result, the product range extends from the smallest rod end of the K or E dimension series (DIN ISO 12240-4 / DIN 648) with a diameter of a mere 4 mm up to the largest spherical plain bearing (DIN ISO 12240-1 / DIN 648) with a diameter of 420 mm.

Enormous loads

for spherical plain bearings and rod ends

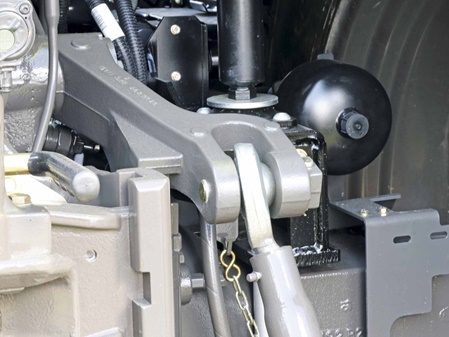

On commercial vehicles, LFD spherical plain bearings are used for exterior connections, controls, stabilisers and for the movement of heavy loading hatches, which are often connected to hydraulic cylinders. This also includes areas of trailer technology and earthmoving machinery.

Depending on the respective application, the spherical plain bearings have various tasks in completely different machines. In part, they are highly visible and provide a degree of mobility that is as free of resistance as possible. Everything that tilts, swivels and turns requires agility. This can most easily be observed in companies that are responsible for the manufacture or maintenance of mobile work machines.

Spherical plain bearings and rod ends

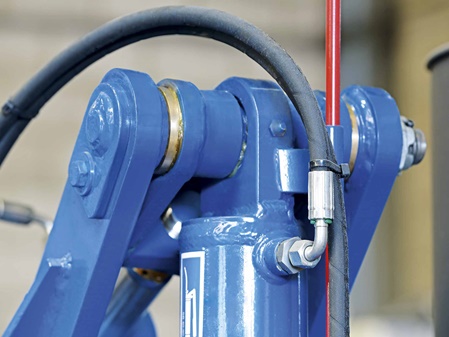

in hydraulic cylinder technology

The use of LFD spherical plain bearings and rod ends is very diverse in hydraulic cylinder technology. Usually, the rod ends are secured with screws or welded on to piston rods and piston tops. Folding cylinders are used in agricultural technology for the adjustment of the working width with spray rod assemblies, tedders, seed drills and meadow trains.

The track width adjustments of various vehicles are performed with the use of hydraulic cylinders, chassis cylinders with spherical plain bearings control the height adjustment, plough turning cylinders and bale grabbers, equipped with rod ends, can also be controlled hydraulically. In part, even the shock absorbers of the chassis are fitted with spherical plain bearings. Additionally, rod ends are used in turnbuckles.

Soil cultivation machinery such as boom mowers is exposed to enormous loads, which are caused by the type of ground conditions and extreme weather influences. The multi-part outriggers are mounted on a rotary column, the swivelling area is safeguarded by hydraulic cylinders.

The LFD spherical plain bearing technology has proven itself during the high force loads due to impacts as well as loads as a result of dust particles, sand, but also boulders.

Reversible ploughs are fitted with variable rod assemblies for the stepless adjustment of the cutting width. These are integrated in the frame. Often hydraulic non-stop systems provide the required degree of mobility.

Here LFD rod ends are the right choice. Forged ploughshares and quenched and tempered mould boards additionally ensure robust attachments.

Further informations: www.lfd.eu und www.gelenklagertechnik.de