Egg production

HIGH-TECH for laying hens

How the family business FIENHAGE ensures

that the raw eggs are handled with the greatest of care during production.

End consumers look

very closely when they purchase eggs

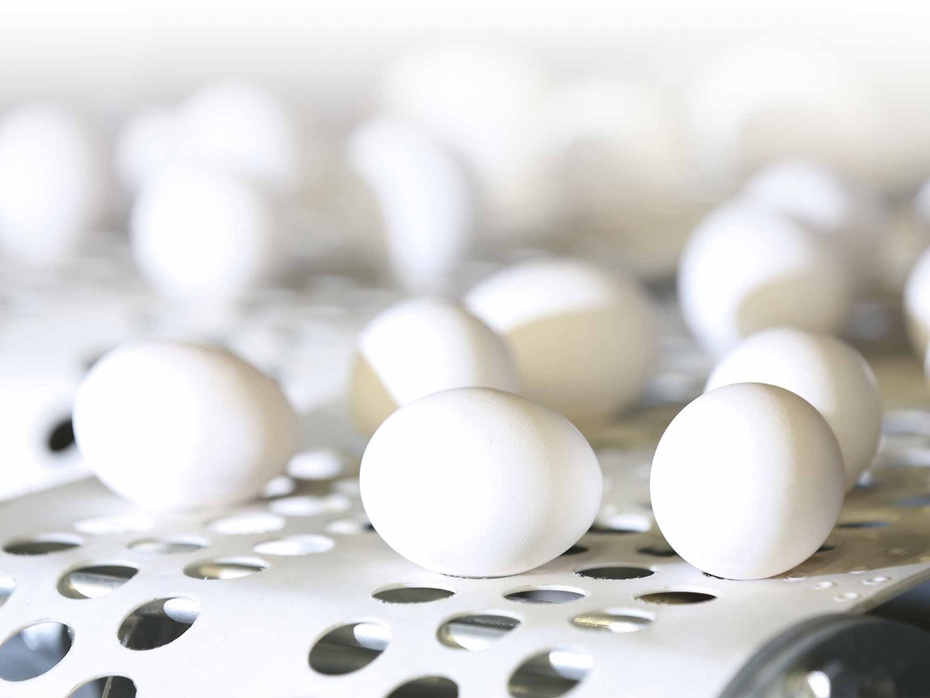

The smallest crack in the shell and the carton will remain on the shelf. This is one of the greatest challenges for egg production. All the more, as contrary to free-range farming an economical egg production with species-appropriate animal husbandry is practically only possible with space utilisation over several levels. During the production process alone, this requires demanding transport logistics. Only 0.1% of the production, i.e. only each thousandth egg may become damaged.

The family business FIENHAGE Poultry-Solutions GmbH is a recognised partner for poultry equipment. It produces systems, which range from the rearing of laying hens up to the packaging. As essential products these include special guide units for the crosswise egg collection and the S-curve system for the transport from the aviary to the cross conveyor.

Designed for economy

LFD bearings as decisive components

for requirement-specific transport solutions in egg production

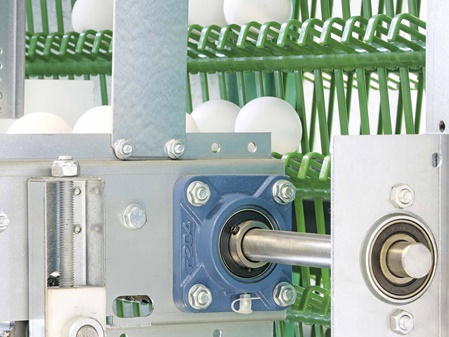

Even though the eggs are positioned on the guide unit for the crosswise egg collection without touching each other, they are placed very close together. For this reason, the conveyor belt must run virtually free of vibrations and juddering – and this with lengths of up to 150 m.

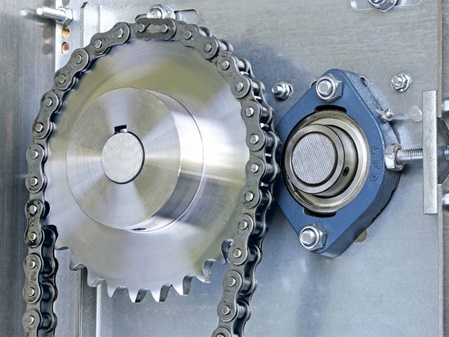

The same applies to the tackling of height differences, which in practice in some instances can be 8-9 m. With these dimensions, the quality of the bearings is a decisive construction criterion. FIENHAGE relies on the precision products of the German manufacturer LFD.

Here, the continuous load of the bearings does not pose the specific challenge. Instead, the other aspects that the transport solution and therefore also the bearings must meet: Soiled environment, maintenance-free operation and an extraordinarily long service life.

Active support as a factor for success

Here, the continuous load of the bearings does not pose the specific challenge. Instead, the other aspects that the transport solution and therefore also the bearings must meet: Soiled environment, maintenance-free operation and an extraordinarily long service life.

FIENHAGE delivers worldwide and for this reason tests extreme application situations. In the course of this testing, the company among others intentionally installs teeth offset in the test assemblies. Under such conditions, operating periods of up to 15 years are simulated.

Selected bearings must work flawlessly along such a time span without the need for re-lubrication. LFD supports FIENHAGE in regard to the construction and testing with advice and assistance in order to ensure that this objective is achieved. The support service in this collaborative partnership has been so successful that FIENHAGE’S systems equipped with LFD bearings met the required service life without difficulty.

The technology presented here ensures that the eggs reach the kitchen table intact. And when they taste good, then a successful start of the day is ensured.

More information: www.lfd.eu/en