Feed mixer wagon

Self-loading feed mixer wagon

V-MIX Fill Plus LS self-loader

As a German owner-managed company, BvL Maschinenfabrik manufactures feed mixer wagons with a separate loading device and an additional cutting tool at its production location in Emsbüren.

In the LS version, the V-MIX Fill has its own cutting unit with an active blade system. It easily cuts through any ensilage. Ensilage slices of up to 40 cm are smoothly and cleanly cut out of the ensilage wall.

Self-removal and loading

The self-loader V-MIX Fill Plus LS is an all-round talent and takes care of removal, loading, mixing and feeding all-in-one. This provides enormous work comfort for the farmer. The cutting unit of the self-loading feed mixer wagon ensures a perfectly smooth cutting surface. In this manner, oxygen ingress into the ensilage is prevented as far as possible and the risk of reheating is minimised.

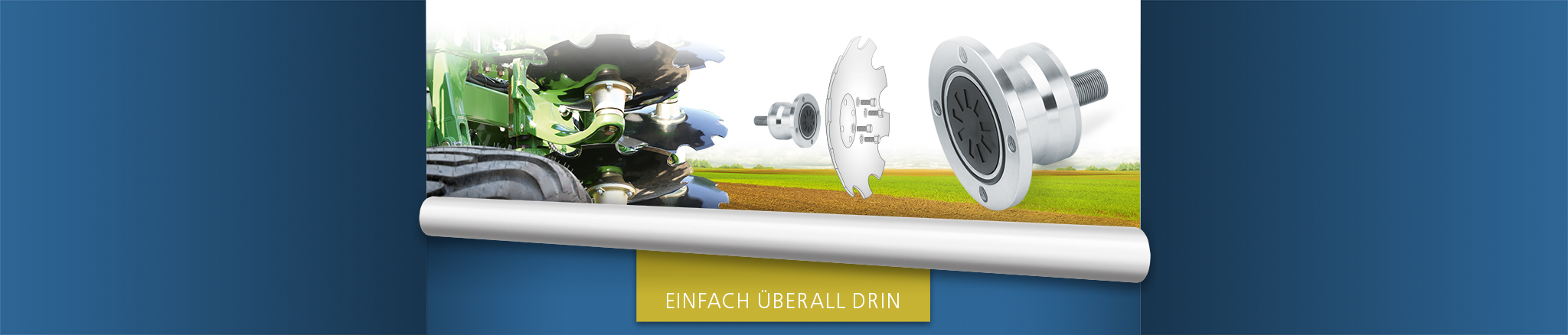

The lowering mechanism supports the easy cut with little pressure. The machines are equipped with reliable LFD flange bearings manufactured in accordance with both German as well as international standards and are fitted with ball bearings as well as spherical plain bearings and hydraulic pivot heads, installed in an easily accessible manner.

LFD bearings support the smooth operation and compensate possible misalignments by means of bearing units.

The LFD flange bearings are installed outside of the machines, facilitating a possible re-lubrication, safeguarding easy maintenance. In regard to the cooperation, BvL design manager Markus Postmeier confirms LFD provides both reliable bearings as well as good support.

“We have encountered no problems in this regard and are very satisfied,” Postmeier states in an interview.

Power mixing auger optimally utilised

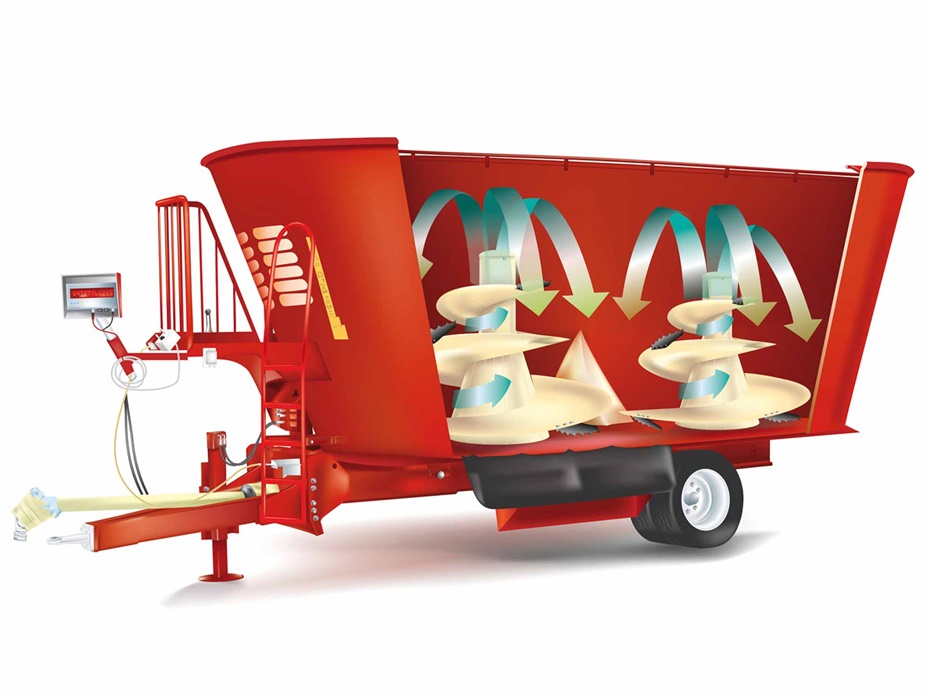

The centrepiece of the feed mixer of the V-MIX range is the power mixing auger. It ensures a particularly gentle and smooth mixing process, as a result of which the structure of the feed in the mixing container is maintained as well as possible. The mixing augers in the mixer wagon’s container can be adjusted optimally for the different feed types by means of blade adjustment.

The power mixing augers in the vertical type are optimally adapted to the shape of the mixing container. The conical and slim auger shape enables a high volume capacity as well as an extremely easy and structure-gentle mixing process. In this manner, the full size of the mixer wagon can be utilised, irrespective which container volume is present, without having to forego the required homogenous mixing quality. Entire round and square bales are easily dissolved.

High variant variety

Wide product range of feed mixer wagons

BvL offers one of the widest ranges of products in feed technology of livestock. Irrespective whether these are external loaders, self-loading mixing wagons with a built-in cutting unit or self-propelled with patented structure roller. Solutions are also offered for individual stables with stationary mixing technology. Feed mixer wagons by BvL are available in a size of 3.5 m³ to 46 m³ or mixers fitted with a single auger or up to three augers.

In the dual or triple auger mixing wagons, the asymmetrically arranged mixing wedges in the container ensure the feed exchange between the individual mixing augers. An optimal material flow with a high-volume utilisation is combined with low power requirements as a result of the arrangement of the mixing wedges.

Patentiertes EDS-System dosiert exakt

The EDS system (Exact Dosing System) ensures a quick and even discharge even without a conveyor. As a result of the asymmetrically arranged discharge openings, the feed is laterally set down in a swath without being run over.

Discharge systems and accessories

Feed mixer wagons are adjusted by BvL according to the conditions at the respective location. In regard to the discharge, the farmer can choose between an EDS discharge door, which is fitted at the sides or in the rear of the machine or a cross conveyor, which is positioned at the front or rear of the machine. Combinations from these discharge methods can also be implemented.

BvL self-loaders can generally be equipped with a cross conveyor at the front or rear. The dual auger mixers of the V-MIX Fill Plus LS range also offer the option of a lateral EDS discharge door.

Additional options in regard to discharge are the feed slide (powered either mechanically or hydraulically) or in the form of a conveyor elevator, which correctly transports the feed into feed troughs.

Mixing wedge

In the dual or triple auger mixing wagons, the asymmetrically arranged mixing wedges in the container ensure the feed exchange between the individual mixing augers. An optimal material flow with a high volume utilisation is combined with low power requirements as a result of the arrangement of the mixing wedges.