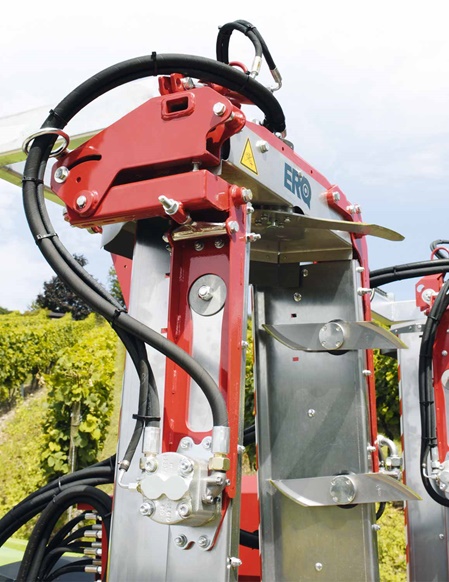

Leaf trimmer in viniculture

Clean cut in viniculture - smooth running ball bearings

The extensive basic equipment of the ERO trimmers ensures a fast installation and comfortable, quick working. After the connection of only two hydraulic hoses and the power supply, the Profi Line type is operational. Additionally, even with high performance and vehicle speed they require very little maintenance.

The deep groove ball bearings made by LFD Wälzlager GmbH provide a frictionless run of the turbo cutters, which are brought into sufficient rotation via a hydraulic motor and a V-belt.

For example, the replacement of the integrated LFD bearings or the re-tensioning of the V-belts, which safeguard a maximum transfer of power, is not necessary and with approximately. 28 litres the system only requires little oil.

Turbo-rotation of the blades

The Elite Comfort type offers a comfort control with Joystick control, as a result of which only a single acting control valve and a pressure-free return on the tractor is required.

Increase of productivity

The model variants L and straddle are available in a one-sided or two-sided version. All cutting elements are each equipped with a separate collision protection. The user can select the respectively suitable cutting unit from the seven different cutting lengths of 100 cm to 195 cm.

For the safe movement on public roads, the cutting elements can be retracted completely and the top blades can be folded rearwards. An optimal view when working and driving on public roads is also ensured.

Extensive adjustment options

Great value was placed during the development of the stainless steel side component to ensure that the drive train is absolutely maintenance-free. During the design phase, cutting forces as well as axial forces during operation were measured and taken into account. The extensive adjustment options of the ERO trimmer allow the use in all types of training. It can be attached to both narrow tractors as well as plantation or standard tractors. Large areas with wide rows can also be processed quickly and effortlessly.

Perfect result

at a high speed

The two cutting units can be adjusted independently from each other both in height as well as in inclination and can be moved laterally, enabling trouble-free working in terraces. All models are tested in accordance with DIN EN 706.

Smooth running thanks to LFD bearings

The 35.5 cm long, especially treated stainless steel turbo blades prevent the deposit of cutting residue on the blade (Teflon effect).

An ideal cutting pattern is achieved due to the treated blade steel and rounded blade shape with a suction effect. The shape of the blades prevents the coiling up and cutting of the wires. Due to the suction effect of the blades, no cutting residue remains in the foliage wall, even small shoot tips and leaves are captured.

The utilised LFD deep groove ball bearing and rod ends are characterised by the consistent, reliable quality and are also suitable for stronger loads, which can occur in daily use. In this manner, LFD produces products for agricultural engineering with a long service life, corrosion resistance, smooth operation, maintenance-free properties and energy efficiency. These properties play a decisive role in the trimmers. Application optimisations are possible with LFD.